When you first mount a new set of wheels on your vehicles, then you will need to do some balancing on them. This process will also need to be done for old tires that have been previously dismounted from the vehicle.

The objective of balancing your tires is to give you a smoother ride when you’re driving your vehicle. This is due to the balance of rotational forces, which is the result of your tires spinning at high speed. Balancing will also help you to extend the usage of your tires and to improve traction on the road.

During the lifetime of your tires, they will lose balance no matter how good and careful the process of balancing you did on them. One of the reasons is tread wear that can happen from usage. Those wear will be able to alter the center of gravity and the distribution of weight on the wheels. This is important to fix because the wheels will only need about 1/4 ounce of imbalance to produce vibration when the vehicle is moving.

Symptoms of Tire Imbalance

The first thing you’ll notice if you have imbalanced wheels on your car is vibration or shakiness when the vehicle is gaining speed. The intensity of the vibration will usually depend on the size and weight of the wheels, the actual size and weight of your vehicle, the quality of suspension, and the sensitivity of the steering wheel. But normally, shakiness will happen starting around 40 mph and increasing.

Note: You also need to be more careful if your wheels are low-profile such as the ones with an aspect ratio of less than 50. This type of tire is usually much more sensitive to imbalance issues, especially if you ride the vehicle frequently on uneven surfaces.

The vibration produced by the vehicle is usually proportional to the speed. To put it simply, you will feel the shakiness become more intense as you gain speed. If you only drive your vehicle around 40 mph, then you will not feel the vibration at all.

A few reasons that can cause balancing issues on your wheels include an improper installation process when mounting the wheels. It can also happen from excessive loss of wheel weight, prolonged usage of wheels, or even defects from the factory.

Wheel weight with clamp-on design may also become loose. This can cause an imbalance in the whole wheel system that will also create vibration. Older wheel weight can also experience the loss of adhesive power that loosens up the wheel.

Wheel Balance Diagnosis

One of the most important things to do when you notice any vibration or shakiness when you write your car is to take the vehicle to the nearest repair facility. Most facilities will have machines to test for tire balancing. They will be able to run compression test to see if you have any balancing issues on your wheels.

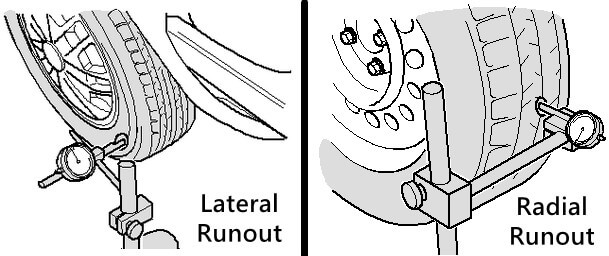

Please remember that vibrations can also happen when you have a runout on your tire. Another possible cause is a damage to wheel bearings from prolonged use. On rear-wheel-drive vehicles, imbalance issues can also arise from an out-of-balance driveshaft.

If you need to find the real cause of speed-sensitive vibration, the first thing to inspect is the wheels. You should look for anything that indicates missing wheel weights or material deposits that are embedded inside the treads.

Meanwhile, if you drive a front-wheel-drive vehicle with rear suspensions, the rear control bushings can also experience excessive flex on them. This will break the rear wheel alignment, which will lead to vibration when you’re speeding.

Uneven surfaces on the wheels can also produce humming noises as well as vibrations when you’re driving the vehicle at high speed. You can check for uneven surfaces by rubbing your hand one way on the wheels and then go the other way.

If you want to reduce the noise and vibration, you can try rotating the wheels in an X-pattern. But, for the wheels that are already worn, you will have no choice other than to replace them. You might also need to get a new set of control arm bushings. And when you get new wheels, make sure to realign the toe alignment properly.

One other thing that you need to pay attention to is the amount of wear on the surface of your wheels. If the damage is more than 50%, then the wheels possibly haven’t been rebalanced since the first time they are used. Make sure that you check for tread depths around the wheel’s circumference. The condition of tread depth will tell you if the damage is evenly distributed. Usually, if the wheels experience more than 1/16 inch of differences, then it means that your vehicle is experiencing an out-of-round condition.

Tire/Wheel Runout Can Cause Vibrations

The normal amount of radial runout that a typical wheel should have is about .050 inches. Some even require less than that number, depending on the type of vehicle’s suspension and steering. If you have low-profile wheels, then they are more prone to experience runout, especially for tires with an aspect ratio of over 50. Wheels with a larger diameter, such as the ones that are more than 18 inches, will be more sensitive to this issue.

One solution that can be used to correct this issue is the “match-mounting” method. This method will rotate the tire so the tire’s high spot will go over the rim low spot. You can also try to wiggle each wheel by hand and see if you can hear excessive noise from the bearings.

A balancing issue can sometimes occur almost immediately from the tire slipping on its rim. The most common cause for this is the usage of lubricants that are silicone-based on the tire bead. The lubricant can also get accidentally applied to the aluminum alloy wheels. Meanwhile, runout can also happen from hard braking or sudden acceleration that can ruin the original balance of the wheel set.

Tire Force Variation Issues Can Cause Vibrations Too

A defect in the manufacturing process of your wheels can cause variations in how the wheels can handle flexing on the tire sidewall. Some will have more resistance to this issue. For the tires that have less resistance, the wheels can wobble even if you have mounted and balanced the wheels properly. Low-profile tires are also more sensitive to high-speed vibration due to this characteristic.

Diagnosing this variation issue can be difficult because it will not show up by just looking at your wheels. Checking the wheel roundness with the dial indicator will also not work. One requirement that you need to have is a load on the tire while you rotate it.

Shops that have tire balancing machines might also have a special roller. This roller will apply a load on the wheels and rotate it. If done correctly, it will be able to detect force variations on the wheels. If you do have force variation issues on your wheels, then the only way to eliminate it is to get a new set of wheels to get installed on your vehicle.

But you don’t need to worry if you have this issue. Most tire manufacturers will give you a free replacement tire if you can prove that the product is indeed a defect.

If you want to use a tire balancing machine, then you can use Hunter Road Force Elite for this purpose. The machine can detect force variations, especially in the tire sidewall.

Wheel Balancing Equipment

To get an accurate measurement of wheel balance, an electronic spin balancer is usually used. This type of balancer will be able to achieve a balanced position both when the wheels are in motion or not. While bubble balancers might be able to do the same job for static balance, spin balancers will still be needed for moving balance.

Modern balancers usually have self-calibrating electronics that can give an extremely accurate reading. The existence of a graphical display will also make it easier to retrieve information regarding your wheel balance.

Modern balancers also operate at lower speeds that can help extend your motor life and also reduce wheel cycle times. On older balancers, the speed usually goes around 500 RPM. But the newer ones will have a much more sensitive sensor on them that will only require a speed of around 100 RPM.

If you encounter a speed-related vibration on your vehicle, it might be caused by an out-of-balance wheel set. You might also have too much runout on the wheel or force variation issues from the manufacturing process. Make sure to get an accurate diagnosis so you can eliminate the vibration problem on your wheels.

WARNING: AVOID USING GREASE OR OIL OR ANY LUBRICANTS WHEN YOU TIGHTEN THE LUG NUTS!

There are three reasons why it is important to properly torque lug nuts. The first reason is to prevent the loosening up of your lug nuts that can result in the wheels coming loose. The second reason is to prevent distortion on the brake rotor that is located behind the wheel. And the third is to reduce the possibility of broken studs.

Caution: Specifications for lug nuts will always call for a clean and dry installation process. This means that you cannot use any oil or grease to torque the lug nuts. Using any oil product will reduce friction between the wheel threads. While it might seem to be a good idea to prevent rust from coming, it can also result in a broken rotor or broken studs due to the reduction of friction.

Before you mount your wheels, make sure to always clean the wheel studs with a wire brush. This process will remove rust and dirt from them. Also, check for the condition of your lug nuts. If they are heavily rusted, the wheels won’t turn easily on the studs. Always make sure that your wheels are also dry before mounting them.