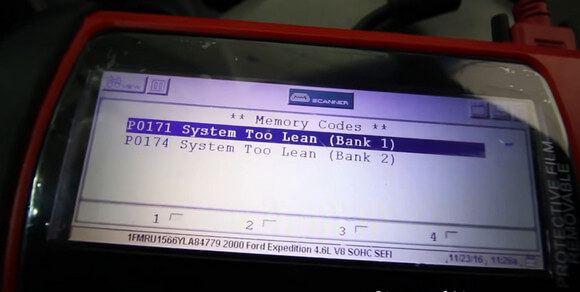

When an engine mixes the air and fuel needed for combustion, there is a chance that the mixture has too much air. When that happens, the mixture is called lean mixture and the powertrain control module (PCM) will set fault codes. In Ford vehicles, there are two codes for this occurrence, which are Ford P0171 for cylinder bank 1, and P0174 for cylinder bank 2.

A code reader or scan tool can be connected into the vehicle diagnostic connector. When one or both of those codes are detected, the Check Engine light will come on. Both codes are also set when the vehicle is driven for a long time.

On Ford vehicles equipped with a V6 or V8 engine with rear-wheel drive configuration, the P0171 lean code is reserved for the cylinder bank 1 located on the right side of the engine.

Meanwhile, on Ford vehicles with front-wheel drive configuration along with a V6 engine, the P0174 is used for the cylinder bank 2 that can be found on the left side of the engine.

What a Lean Code Means

The condition where the engine has too much air in the mixture is called lean mixture, and that happens when the engine is sucking too much air. It could also be caused by the disturbance in the fuel delivering system that makes the engine lack the needed fuel supply. If the condition is left unfixed, an overall poor engine performance could occur. Furthermore, other things could also happen, such as engine sputtering, lean misfire, or rough idling mechanism.

Some possible causes can include the damaged or dirty airflow sensor that can’t read airflow level correctly. The unmetered and excess air can then mix with the fuel inside. The EGR valve could also be the root of this problem when they’re not closed properly, allowing too much airflow. Aside from that, a faulty EGR valve could have different readings due to a broken pressure sensor.

On the fuel side, the engine might have a lack of fuel due to a weak fuel pump, a blockage in the fuel filter, residue depositing on fuel injectors, or simply a leak around the fuel pressure regulator.

If all of those above are good, then a dirty MAF sensor could be the culprit. Cleaning it could be the solution, or just replace it with a new one.

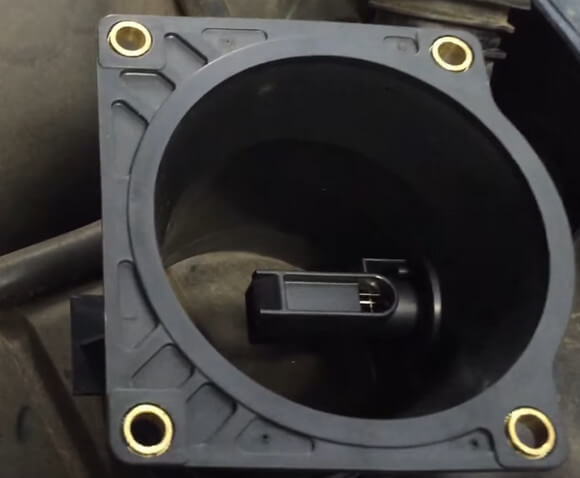

MAF Sensor is Dirty

MAF or Mass Airflow sensor is a tool to read the airflow intake on engines. This sensor is located inside the air inlet tube, a line that inputs air into the engine, next to the throttle body. Due to the importance of correct reading, MAF should always be protected by air filters to prevent dust and other debris being collected on the sensor. If deposits form around it, this condition will slow down the reading and mess up the airflow intake mechanism.

Other than dirt and debris deposits that can cause Ford P0171 and P0174 to occur, the MAF sensor can also get damaged by excess fuel vapors that escape the engine. These fuel vapors have a mixture of chemicals that can form a waxy coating on the sensor. This can lead to the inability of the sensor to report accurate reading, and in turn, will push the powertrain control module (PCM) to not add enough fuel. The result is a lean air/fuel mixture that could lead to other engine problems. (More details can be seen on Ford TSB 98-23-10).

Using a scan tool can help identify the condition of the MAF sensor. With scanning tools, PID data can be read to see the fuel trim values when you run your engine. The data should show a fuel trim value at around minus 3 to 5 if the sensor is clean. But when it’s dirty and the engine is running high, the fuel trim can go to more than 5 and higher which is a sign of a lean fuel mixture.

To remedy this problem, you can clean the sensor by first opening and disconnecting the air inlet tube. Right at the tube opening, spray some electronics cleaner liquid around the wire element inside the MAF sensor. Let it soak for a while before you reconnect the tube again. If the problem persists, try the method again until the sensor is thoroughly cleaned.

But if you have tried cleaning the MAF sensor and the fault lean codes are still beeping, you might need to replace it with a newer unit.

Vacuum Leaks

If the Ford P0171 and P0174 lean codes aren’t caused by a dirty MAF sensor, another cause that might be possible is a vacuum leak in the engine. There are many places around the engine where these leaks could occur, including the intake plumbing, throttle body gasket, vacuum hose connections, or the intake manifold gaskets.

A scan tool is again useful to diagnose the leaking situation. If the scan tool has been connected, choose the PID data menu after starting the vehicle engine. The attention should be put on the trim values. A detection reading that shows fuel trim values of more than 5 should confirm the existence of vacuum leaks. You can even double-check the reading by revving the engine to around 2500 RPM. If vacuum leaks are present the fuel trim values should drop to around zero all the way to minus 3. (Ford TSB 04-17-4 explains the procedure to correctly read fuel trim level involving vacuum leaks).

On Ford vehicles with 3.8L engines equipped with split-plenum intake manifolds, some of the most crucial parts of the upper plenum can deteriorate and be damaged from use. These parts include the port gaskets and isolator bolt assemblies. This is often the result of oil material getting sucked through the PVC system and all the way to the intake manifold.

Consulting the Ford TSB 03-16-1, the fix will involve several steps, starting by removing the manifold plenum. Then, the damaged gaskets or bolts should be replaced with ones that work well. To minimize the amount of oil being seeped into the plenum, replace the front valve cover and the fuel pressure regulator hose. The last step is to reflash the PCM to make it less sensitive when the lean fuel mixture occurs in the future.

Fuel Volume Delivery is Low

Another side of the lean fuel mixture is the lack of fuel being delivered inside the engine. A weak fuel pump, a blocked fuel filter, low voltage on the fuel pump or even a leak in the pressure regulator could all cause the condition.

The PID data should be read with the help of a scan tool. The gathered data should then be analyzed to see the delivery problem with the fuel that may be causing lean fault code to ensue. If the data shown is different than the required specification, then there might be a problem that needs to be fixed in the fuel delivery system.

When using the scan tool, it’s better to read the data first when the engine is idling. If the engine is idle, the fuel trim value should show around zero. When the engine speed and load are increased, an engine with fuel delivery problems should show a higher number of fuel trim values. But if the number doesn’t change as you add load to the engine, then the problem is not connected to the low fuel volume.

Another thing to look for is the condition of fuel injectors. The injectors might work fine when the engine load is low or at idle, but as the load increases, dirty fuel injectors might not be able to keep up with the engine demand. The effect is similar to a weak fuel pump, which leaves the air and fuel mixture to have too much air for optimal engine condition.

Cleaning the fuel injectors should be an easy step to solve this problem. If the debris is too much, a simple cleaning procedure with regular cleaners might not be enough. Always consult a professional when you need to have injectors totally cleaned.

Another Alternative: A Bad DPFE Sensor

A damaged or impaired EGR differential pressure sensor could also be the cause for Ford P0171 and P0174. This is actually the situation that is more likely to happen, as the DPFE sensors normally need to be changed after the vehicles scored around 60,000 miles on the odometer. Age could also be the factor because a replacement is needed after five years of usage.

To find the DPFE sensor, the location is around the exhaust gas line where it will be attached to the hoses that send exhaust to the EGR valve. You can notice the sensor by the original housing around three inches long that is made with aluminum.

The most common problem with this sensor is the corrosion inside it that can lead to reduced sensitivity. In turn, the EGR flow is reported lower than it should. This lower number will activate the PCM to increase the EGR flow, which creates an excess air supply, leading to a lean condition. Because of this, a P0401 code could also be shown along with the Ford P0171 and/or P0174.

If the P0401 shows up, that usually means a bad DPFE sensor instead of a problem with the EGR valve. Changing the DPFE sensor is usually cheaper, around USD 50, and it will usually minimize the occurrence of codes P0401 as well as P0171 and P0174.