When the engine is not start or running properly, it is likely that the fuel pump does not provide sufficient fuel pressure and fuel volume to the engine. Some problems will occurs if the fuel pressure is low, it can cause hesitation and stalling, a rough idle, hard starting, or misfiring. Engine won’t starting when no fuel pressure, or when fuel pump fails, it may cause the engine to quit while you are driving.

The sensitivity of the fuel injected engine to the fuel volume as well as the fuel pressure so high. The driveability and engine failed to start issues sometimes caused by low pressure. The possibility the engine to start and idle normally can occur even though the pressure from the pump is adequate but the volume is insufficient, however when the engine cruising at highway speeds or accelerating hard, or is under load, the engine will lose the power because the engine starve for fuel supply.

Engine Cranks But Will Not Start

The reason the engine will not start is because a dead fuel pump, the engine itself has issue like broken timing belt or ignition system problem. Check the spark

The spark is the first thing to check. To check the spark, while the engine is cranking connect the spark plug tester into plug wire. To have a good electrical connection, the spark plug tester must be grounded to the engine block.

CAUTION: Watch out for electric shock injured. It very dangerous because can be deadly. So, while the engine is cranking DO NOT touch any of the spark plug wires.

If there a coil-on-plug ignition system on engine, in the end of the coil place a spark plug after one of the coils removed. In order for the plug to touch the metal on the engine, place the coils and plugs.

When no issue with the ignition system because it working properly, while cranking the engine you should see a series of sparks. The ignition system in trouble if there is no sparks come out, this problem may caused by bad ignition coil, bad crankshaft position sensor or bad ignition module.

If the engine has rubber timing belt and an overhead camshaft, check the timing belt. Inside the plastic cover at the end of the engine you can find the belt. If you want to see the belt, you need removing some screws cover and pulling it back. Check and make sure no issue on belt, if everything is OK, try turn the engine on, if it cranked, probably your problem is not a compression.

If the damage occurs on the gear at the bottom of the belt or if they loosen up, the timing belts can jump time. If the engine gets overheated and the engine runs out (low) of oil, this could lead to the overhead camshaft to break or seize. But that is not a problem, when the engine cranked but the cam gear turn.

CAUTION: When engine is cranking, stay away from the belt and gears.

Lack of fuel is possibly cause the engine won’t start if both compression and ignition are OK. So what the problem now? the fuel pump or another else?

Fuel-related issue that possible caused no start on engine:

- Low fuel pressure. Defective fuel pressure regulator, low voltage to the pump, restricted fuel line, or weak pump.

- A dead fuel pump, could be the pump wiring circuit faulty, the pump or pump relay pump fuse.

- A plugged fuel filter.

Engine still doesn’t start even though the normal pressure on the engine is generated by the pump (pump runs normally), possible issue is:

- Shorted fuel injector, none will operate because the voltage from the other injector is robbed.

- The PCM don’t receive pulse signal from the injectors. Driver circuit PCM is bad, problem of wiring harness, or no crank or cam sensor input to the PCM.

- Fuel injector no voltage, bad relay or blown injector fuse.

Fuel Pump Checks

The fuel pump is the first thing you need to check. When engine cranking, does the pump run or not? It is normal to have a little noise from the pump and it should be like that. The pump is not spinning if the no noise come out.

Most of the pumps in the vehicle get energy from the PCM through the relay. To build up pressure, the pump required to run, so after first time the ignition is switched on, for a few seconds the fuel pump is energized by the PCM through the relay and make the pump runs. When the engine started after cranking, the engine does not send RPM signal to PCM, this make turns off the pump because the fuel pump relay is shuts off. Through an oil pressure switch and/or an inertial safety switch the pump circuit can also be connected, so that in case of an accident it will kill the pump.

Fuel pump will not running when the fuel pump relay is bad or faulty. Take off the relay and shake it after you find out it, usually located in the power center (in the engine compartment) you can find the fuel pump relay. When you shake it and inside the relay you hear anything rattling, you need to replace it because the fuel pump relay is broken.

To the fuel pump, route power directly and bypass the relay if you gonna to test the fuel pump. When you bypass the relay and fuel pump is running, there an issue with wiring circuit that supply power to the relay or it can caused by bad relay. It can be tricky and make sure you know which terminals will be jumped when you bypassing the relay. Read online or offline the vehicle fuel pump wiring diagram manual before you attempt this procedure.

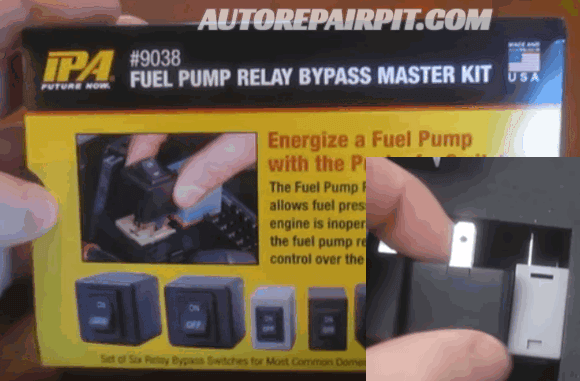

Bypassing a fuel pump is more easier with this tools (named with Fuel Pump Relay Bypass Master Kit), no jumper wires or no wiring diagram. The tool is easy to use and operated. On top has an ON-OFF rocker switch on, so what you need to do is just use test relay to replace your fuel pump relay. Fuel pump need to be energized, it can be done by flip/turn the switch and see the fuel pump is running or not. If fuel pump is runs, bad relay is your problem. If there is no reaction from fuel pump (not runs), check wiring between the relay and pump may be fault or might be bad fuel pump caused the issues.

High resistance at the pump’s ground connection or low voltages in the pump power supply circuit may be affected by other electrical problems.

Continue to Diagnose Fuel Pump (Part 2) : Fuel Pressure Test